4 Best Tempered Glass Roof Construction Measures

With many years of experience in making glass roofs, we would like to share 4 best methods of tempered glass roof construction for you to know.

Step 1: Survey and design tempered glass roof

Process before construction of tempered glass roof. We will send technicians down to the site to survey the terrain. Depending on the location to be installed, we will advise exactly and design.

This step is extremely important in the process of making tempered glass roofs. From the survey step, we can build an overview and offer a price to the customer.

The selection of the glass support frame is reasonable, analyzing the advantages and disadvantages in the construction process. Contribute to reducing the cost of tempered glass roof.

Step 2: Processing the tempered glass roof frame at the factory

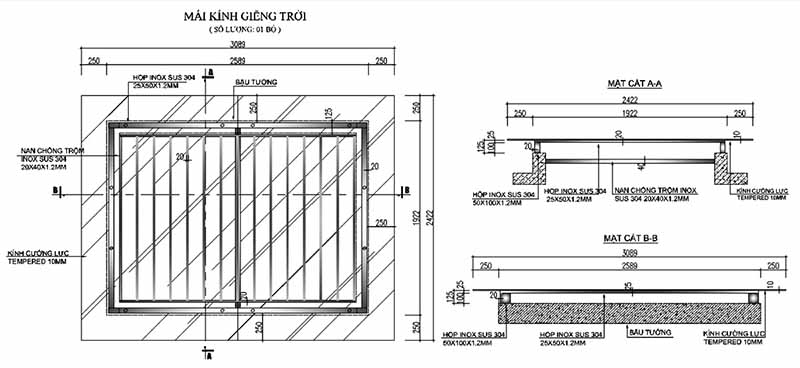

Once agreed on the construction plan. The main part is the roof frame which will be processed at the factory according to the design. The elements of length, width and thickness are all made according to the drawing.

With a steel frame roof, it is necessary to drill with Hiti chemicals or common ramset ø16 – ø20. Steel complex I200 - I300 to increase the strength of the roof, ensuring absolute safety.

In preparation for construction, it is necessary to have adequate equipment and resources to match and ensure the progress and quality of products.

Equipment and auxiliary materials such as iron frames, installation tools, screws, pump glue .... All are indispensable items and need to be fully prepared.

Step 3: Install tempered glass roof at the construction site

Installation of frame structure

Installing the glass roof frame at the construction site is a time-consuming step in the construction process. Solid welds.

This step requires technical supervision, ensuring this mounting frame is the most secure and follows the requirements.

Finishing the steel frame structure, you need to take measurements to place the tempered glass correctly.

Put tempered glass on the iron frame

When the frame is complete, the tempered glass will be installed in the position specified on the drawing. Install glazing directly or use spider legs.

For direct glazing, you need to put rubber on it to create smoothness and adhesion. At this time, the technical team will carry out the installation using machines and manual. For the best installation.

Usually, the tempered glass roofs have a large volume and are installed at high altitude. Therefore, this installation requires the support of specialized machinery for effective installation.

Apply glue and finish

This is the last step that needs to be done. The construction unit will re-check the entire implementation process. This finishing will perform screwing, silicone glue, repaint the welds, scratches to ensure the most complete work.

For glazing directly, put rubber on it to create softness and adhesion. Then there is the glue pump.

Step 4: Acceptance of works and product handover

When the method of construction of tempered glass is completed. The construction unit and the customer jointly conduct the acceptance and re-inspection of the entire project. This process can be implemented or modified as customer needs change.

Customers will conduct acceptance testing for the quality and aesthetics of the project.

When the acceptance test is completed. The construction party hands over and the customer makes payment according to the contract.

Above are 4 construction methods of tempered glass roof that Cuatinhsaigon.org shared. Hope you have a clear understanding of the effective construction steps.

Source: Collector